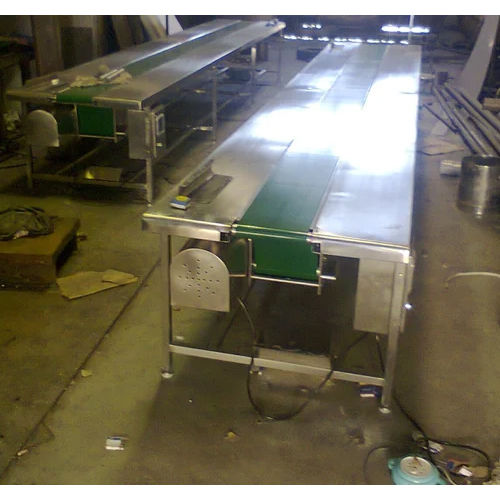

Isolator machine

251000 INR/Unit

Product Details:

- Type Isolator

- Material Stainless Steel

- Computerized No

- Control Mode Semi-Automatic

- Voltage 230 Volt (v)

- Color Gray

- Click to View more

X

Isolator machine Price And Quantity

- 1 Unit

- 251000 INR/Unit

Isolator machine Product Specifications

- No

- Semi-Automatic

- Isolator

- Stainless Steel

- Gray

- 230 Volt (v)

Isolator machine Trade Information

- 1 Unit Per Week

- 1 Week

Product Description

An isolator machine, also known as an isolator system, is a type of equipment used in the pharmaceutical and biotech industries to protect workers and products from contamination during the handling of hazardous materials or substances.

Isolator machines are designed to provide a highly controlled environment, in which materials or substances can be manipulated and processed without exposing workers or the surrounding environment to the risk of contamination. They typically consist of an enclosed chamber or system, which is designed to maintain a highly controlled environment with low levels of airborne particles, humidity, and temperature.

Isolator machines may be used for a variety of tasks, such as the preparation and handling of sterile drug products, the handling of potent or toxic substances, or the manipulation of biological materials. They may also include additional features, such as air locks, HEPA filters, or containment systems, to enhance their safety and effectiveness.

Overall, isolator machines are an essential tool for pharmaceutical and biotech companies, providing a safe and controlled environment for the handling of hazardous materials or substances. They help to minimize the risk of contamination, protect workers and the environment, and ensure the integrity and quality of the products being handled.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email